Kunjungan Pelanggan Aljazair: Lini Pemotong Kumparan Silikon

2025-06-22 12:00Minggu lalu, ditemani oleh staf dan teknisi KINGREAL, seorang pelanggan Aljazair mengunjungigaris pemotongan kumparan silikondi pabrik KINGREAL. Kunjungan ini tidak hanya memberikan pemahaman intuitif tentang lini pemotongan kumparan NGOES, tetapi juga kesempatan penting untuk pertukaran teknis antara kedua belah pihak. Pelanggan Aljazair ini telah terlibat secara mendalam di bidang manufaktur kendaraan energi baru kelas atas selama bertahun-tahun dan memiliki permintaan yang kuat untuk strip sempit baja silikon. Namun, karena kekerasan dan kerapuhan material baja silikon yang sangat tinggi, keausan pemotong selama proses pemotongan sangat serius. Karakteristik ini menempatkan persyaratan yang sangat ketat pada akurasi dan parameter proses lini pemotongan kumparan silikon. Oleh karena itu, teknologi pemotongan baja silikon ultra-tipis selalu menjadi salah satu masalah yang sulit dalam industri baja. Teknologi pemotongan tradisional sering kali gagal memenuhi persyaratan produksi presisi tinggi dan efisiensi tinggi, terutama saat memproses material ultra-tipis.

Kunjungan Pabrik -- Lini Pemotong Kumparan NGOES

Selama kunjungan tersebut, KINGREAL memperkenalkan kepada pelanggan Aljazair desain penelitian dan pengembangan terbaru dari timnya dijalur pemotongan kumparan silikonLini pemotong kumparan NGOES ini dapat memotong baja listrik non-orientasi ultra-tipis berkualitas tinggi dengan lebar hanya 0,1 mm. Terobosan teknologi ini menarik minat besar pelanggan, dan mereka berharap dapat mengamati pengoperasian lini pemotong kumparan silikon di lokasi untuk lebih memahami kinerja aktualnya.

Para insinyur KINGREAL memperkenalkan proses penelitian dan pengembangan lini pemotongan kumparan NGOES ini secara detail. Berangkat dari berbagai aspek seperti sifat material, akurasi peralatan, dan parameter proses, mereka melakukan riset dan optimasi mendalam pada setiap tahapan dalam proses pemotongan. Setelah uji coba dan eksplorasi berulang kali, tim akhirnya menemukan parameter alat dan proses pemotongan terbaik, berhasil menembus hambatan teknis, dan mewujudkan pemotongan baja silikon ultra-tipis 0,1 mm. Keberhasilan teknologi ini tidak hanya menyediakan produk berkualitas tinggi bagi pelanggan, tetapi juga meletakkan fondasi bagi kemajuan teknologi di seluruh industri.

Di lokasi, KINGREAL mengundang pelanggan Aljazair untuk mengoperasikan lini pemotongan kumparan NGOES secara langsung. Dengan menyesuaikan parameter pada panel kontrol, pelanggan berhasil memotong strip sempit dengan ukuran yang dibutuhkan. Pelanggan memuji kemampuan pemotongan presisi dan geser longitudinal dari lini pemotongan kumparan silikon ini dan yakin bahwa teknologi ini dapat memberikan konsistensi dan akurasi ukuran produk untuk produksi selanjutnya. Baik lebar maupun panjang, lini pemotongan kumparan NGOES ini dapat memenuhi persyaratan ketat pelanggan dan menghasilkan produk strip baja silikon berstandar tinggi.

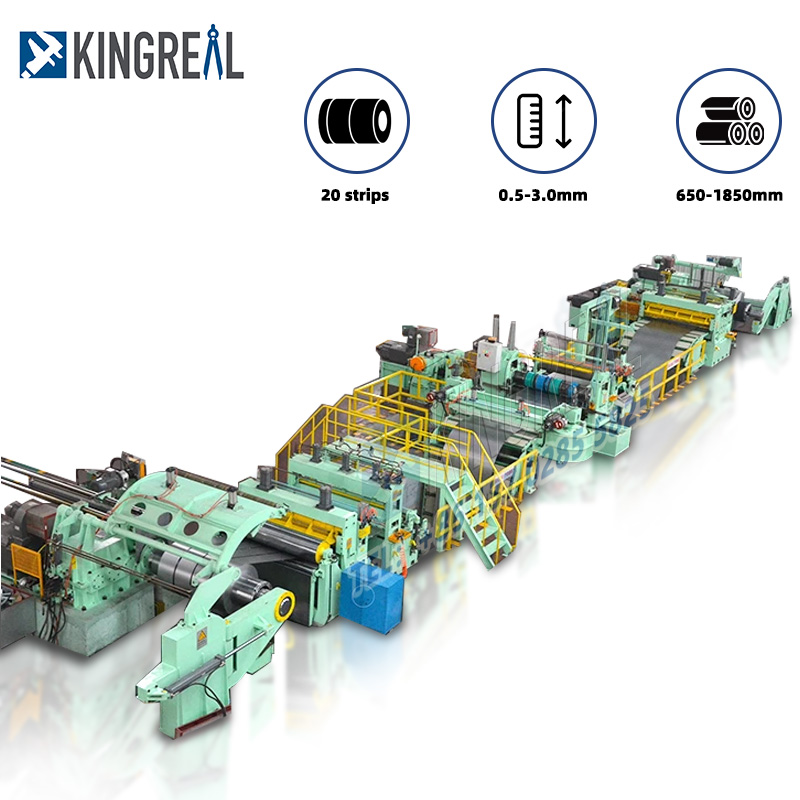

Parameter garis pemotongan kumparan silikon ini:

| Barang | Nilai |

| Ketebalan material | 0,15 hingga 0,5 mm |

| Mengurangi jangkauan ekspansi | Φ480 hingga Φ520mm |

| Lembar maks. | 1250 mm |

| Berat kumparan | 5 hingga 8 ton |

| Poros pemotong | Ukuran Φ125 mm |

| Diameter luar bilah | Ukuran Φ250 mm |

Strip pemotongan | 20 hingga 1250mm |

Kecepatan pemotongan | 50 hingga 120m∕menit |

| Duri | ≤0,02 mm |

| Kelurusan | ≤0,2 mm/2 m |

Toleransi | ±0,1 mm |

Pisau pemotong | 12 set |

Konsumsi daya | 55 kW |

Dimensi garis | 12,6m × 6,5m × 2m |

| Berat kotor | sekitar 20 ton |

| Catu daya | Tegangan 380V AC 50Hz |

Dalam komunikasi tersebut, pelanggan asal Aljazair menyampaikan harapannya untuk mengurangi emisi konsumsi energi dan berupaya mewujudkan produksi ramah lingkungan. Gagasan ini sejalan dengan konsep desain KINGREAL untuk lini pemotongan kumparan silikon. KINGREAL berkomitmen untuk mengadopsi teknologi hemat energi mutakhir, berupaya mengurangi limbah dan gas buang dalam proses produksi, mengurangi dampak terhadap lingkungan, dan mematuhi konsep pembangunan berkelanjutan.

Bengkel Inspeksi Bahan Baku

Setelah itu, KINGREAL mengajak pelanggan Aljazair mengunjungi bengkel bahan baku. Di sini, pelanggan Aljazair dapat secara intuitif memahami bahan dan komponen berkualitas tinggi yang digunakan dalamJalur pemotongan kumparan NGOESBahan baku ini telah menjalani kontrol dan pengujian kualitas yang ketat untuk memastikan keandalan dan stabilitas lini pemotongan kumparan silikon. Selama pengoperasian jangka panjang, bahan berkualitas tinggi ini dapat mempertahankan kondisi kerja yang efisien, mengurangi kegagalan dan waktu henti, sehingga meningkatkan efisiensi produksi.

Selama proses observasi, pelanggan sering mengangguk dan mengapresiasi pemilihan material dan kontrol kualitas KINGREAL. Ia yakin bahwa bahan baku berkualitas tinggi adalah dasar untuk memproduksi lini pemotongan koil NGOES berkinerja tinggi.

Di akhir kunjungan, pelanggan Aljazair menyatakan kepuasannya yang luar biasa dan mengajukan persyaratan yang lebih rinci. Ia berharap para insinyur KINGREAL dapat segera memberikan rencana manufaktur lini pemotongan kumparan silikon agar dapat memenuhi kebutuhan produksinya dengan lebih baik dalam kerja sama di masa mendatang. Umpan balik positif dari pelanggan tidak hanya menunjukkan pengakuan atas teknologi KINGREAL, tetapi juga meletakkan dasar yang baik untuk kerja sama lebih lanjut antara kedua belah pihak.

Tindakan pencegahan untuk Jalur Pemotongan Kumparan Silikon

Pengoperasian jalur pemotongan kumparan NGOES 1. Harus ada 2 hingga 5 pekerja di jalur produksi. Personel lain harus menjauh dari jalur produksi.garis pemotongan kumparan silikon. 2. Tanda kuning harus dipasang di sekitar jalur pemotongan kumparan NGOES, dan area terlarang harus ditandai pada pagar. 3. Pastikan untuk menambahkan oli pelumas ke roda gigi dan rantai pada jalur pemotongan kumparan silikon ini. 4. Pasang kumparan dengan benar agar beratnya tetap seimbang. Troli kumparan harus memasang dan membuka gulungan kumparan ke dalam decoiler sebelum dapat diatur ulang. 5. Tekan kepala kumparan dengan rol traksi terlebih dahulu, lalu buka kemasan kumparan untuk mencegah kepala kumparan memantul ke atas. 6. Pada saat mesin pemotong kumparan NGOES sedang berjalan, operator dilarang berdiri di atas kumparan. 7. Dilarang menggerakkan kumparan langsung dengan tangan. 8. Jika terjadi masalah pada jalur pemotongan kumparan silikon, segera hentikan mesin untuk diperiksa. 9. Jangan membongkar atau mengganti sirkuit. Jika Anda memiliki pertanyaan, silakan berkonsultasi dengan teknisi profesional. |  |

Perawatan jalur pemotongan kumparan NGOES

Pertama, periksa apakah ada bagian-bagian pada jalur pemotongan kumparan silikon yang longgar atau rusak. Pipa oli harus bebas dari penyumbatan dan diisi ulang secara teratur. Setelah pekerjaan selesai, komponen listrik, hidrolik, pneumatik, dan komponen lainnya harus dipastikan normal. Setelah pekerjaan selesai, catu daya utama harus diputus dan jalur pemotongan kumparan NGOES otomatis harus dibersihkan.