Kasus: Garis Potong Berkecepatan Tinggi Sesuai Panjangnya

2025-03-27 12:00KINGREAL adalahperalatan potong logam sesuai panjangpemasok yang mengintegrasikan R&D, desain, produksi, dan penjualan, dan berkomitmen untuk menyediakan solusi manufaktur jalur potong memanjang berkecepatan tinggi yang disesuaikan bagi pelanggan. Sejauh ini, berbagai jalur potong memanjang baja tahan karat KINGREAL, sepertiperalatan pemotongan logam geser putar sesuai panjang, peralatan pemotongan logam geser tetap sesuai panjang, jalur pemotongan baja tahan karat sesuai panjang dengan mesin perataan ganda, jalur pemotongan baja tahan karat sesuai panjang dengan meja susun ganda, jalur pemotongan baja tahan karat sesuai panjang, dll., telah berhasil dijual ke Mesir, Qatar, India, Rusia, Indonesia, UEA, Turki, dan negara-negara lain, serta telah menjalin hubungan kerja sama yang erat dan bersahabat dengan para pelanggan. Berikut ini adalah ringkasan terperinci dari beberapa proyek yang berhasil.

Jalur Pemotongan Panjang Berkecepatan Tinggi di Rusia

Di sebuah pameran, staf KINGREAL berkomunikasi dengan seorang pelanggan Rusia. Kekhawatiran utama pelanggan Rusia tersebut adalah karena perluasan skala produksi, peralatan pemotongan logam asli tidak dapat lagi memenuhi kebutuhan produksi saat ini. Selain itu, terdapat sejumlah besar tautan pada peralatan asli yang memerlukan pengoperasian manual, yang menyebabkan bahaya keselamatan dan efisiensi yang tidak stabil. Staf mendengarkan dengan saksama kebutuhan pelanggan Rusia tersebut dan menanyakan tentang ketebalan, bahan, dan ukuran bengkel pabrik kumparan logam tersebut.

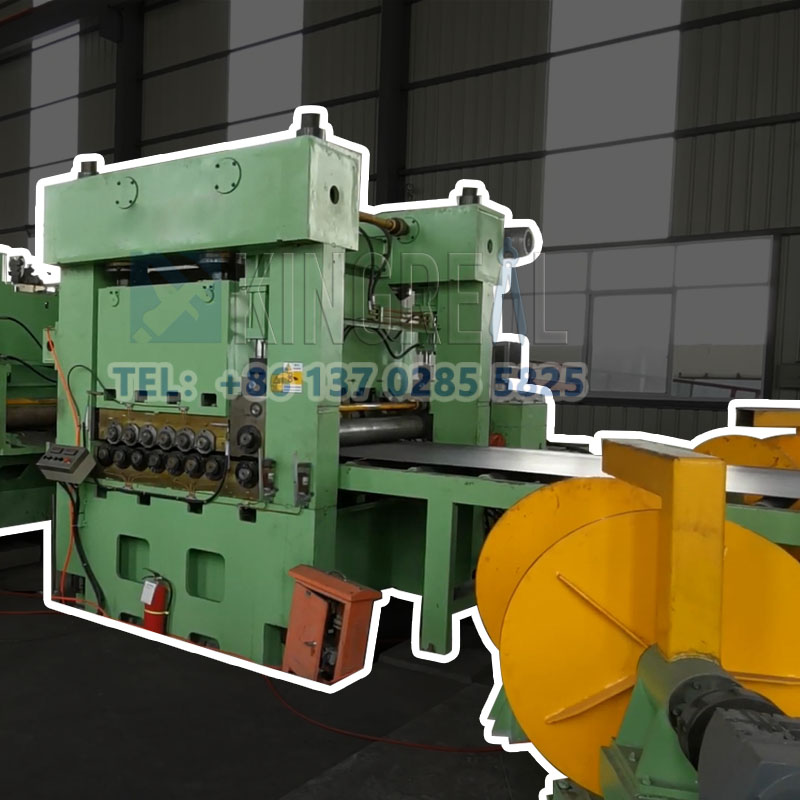

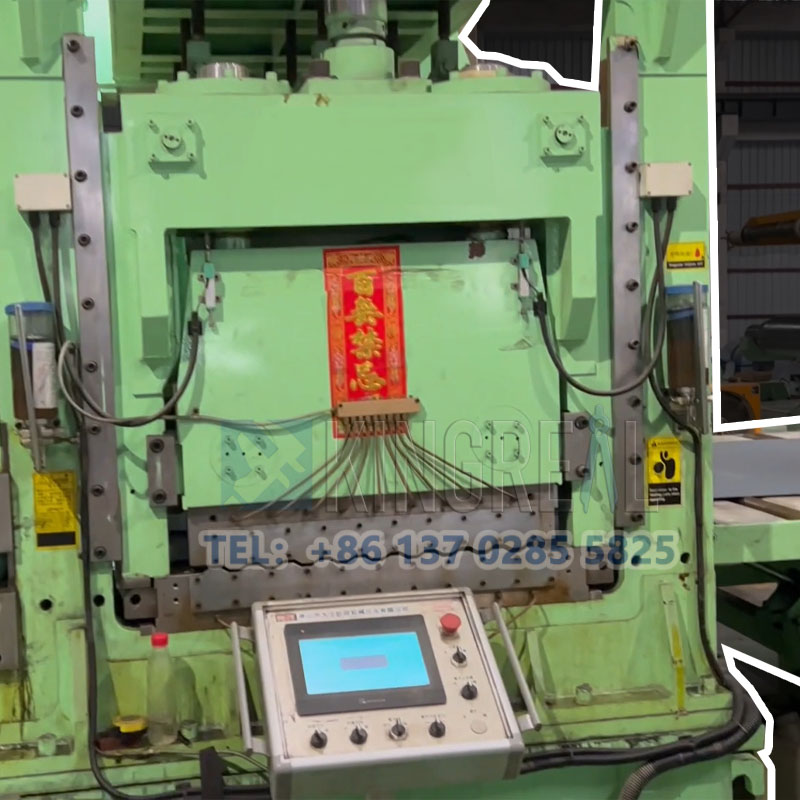

Setelah komunikasi yang cukup, KINGREAL merancang sistem yang sepenuhnya otomatisgaris potong berkecepatan tinggisesuai dengan gambar pelanggan Rusia dan kebutuhan produksi aktual. Lini potong baja tahan karat dilengkapi dengan beberapa komponen utama seperti decoiler, leveler, mesin potong memanjang, perangkat pengumpulan limbah, sabuk konveyor, dan meja susun, sehingga mencapai otomatisasi maksimum. Operator hanya perlu mengatur parameter yang relevan, dan peralatan potong memanjang logam dapat berjalan secara otomatis, memotong secara akurat sesuai dengan panjang yang telah ditetapkan pelanggan Rusia, dengan kecepatan hingga80m/menit.

Keberhasilan proyek ini tidak hanya memecahkan hambatan produksi pelanggan Rusia, tetapi juga meningkatkan efisiensi dan keamanan produksi secara signifikan, sehingga memungkinkan pelanggan Rusia untuk mengatasi lonjakan volume pesanan dalam produksi berikutnya dengan lancar.

Peralatan Pemotongan Panjang Tugas Berat di Turki

Pelanggan asal Turki ini adalah pelanggan lama KINGREAL. Ia telah membeli peralatan lain sebelumnya dan memiliki tingkat kepercayaan yang tinggi terhadap KINGREAL. Kali ini ia membutuhkan jalur potong baja tahan karat untuk memproses gulungan logam dengan ketebalan hingga 18 mm, tetapi banyak pemasok di pasaran mengatakan bahwa mereka tidak dapat memenuhi persyaratan ini. KINGREAL tahu bahwa ini adalah tugas yang menantang, tetapi tetap mengatakan bahwa mereka dapat memberikan solusi kepada pelanggan.

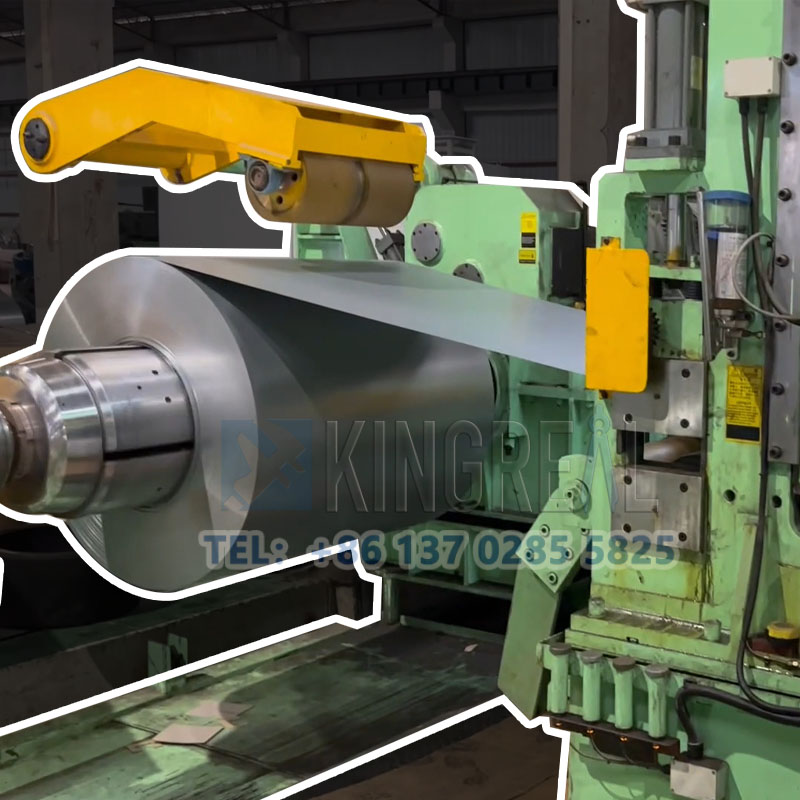

Setelah diskusi teknis yang terperinci, para insinyur KINGREAL akhirnya merancangtali potong tugas berat sesuai panjangnyauntuk pelanggan Turki yang dapat menangani ketebalan mulai dari6-20mmGaris potong baja tahan karat menggunakan desain struktural berkekuatan tinggi dan teknologi pemotongan canggih untuk memastikan kestabilan dan presisi saat memproses gulungan logam tebal.

Melalui jalur potong tugas berat ini, pelanggan Turki memecahkan masalah pemrosesan gulungan logam berat, yang tidak hanya meningkatkan efisiensi produksi tetapi juga meningkatkan kualitas produk. Desain jalur potong tugas berat ini memungkinkan pelanggan Turki untuk menonjol dalam persaingan pasar dan memperoleh lebih banyak pesanan.

Peralatan Pemotongan Panjang Terbang di UEA

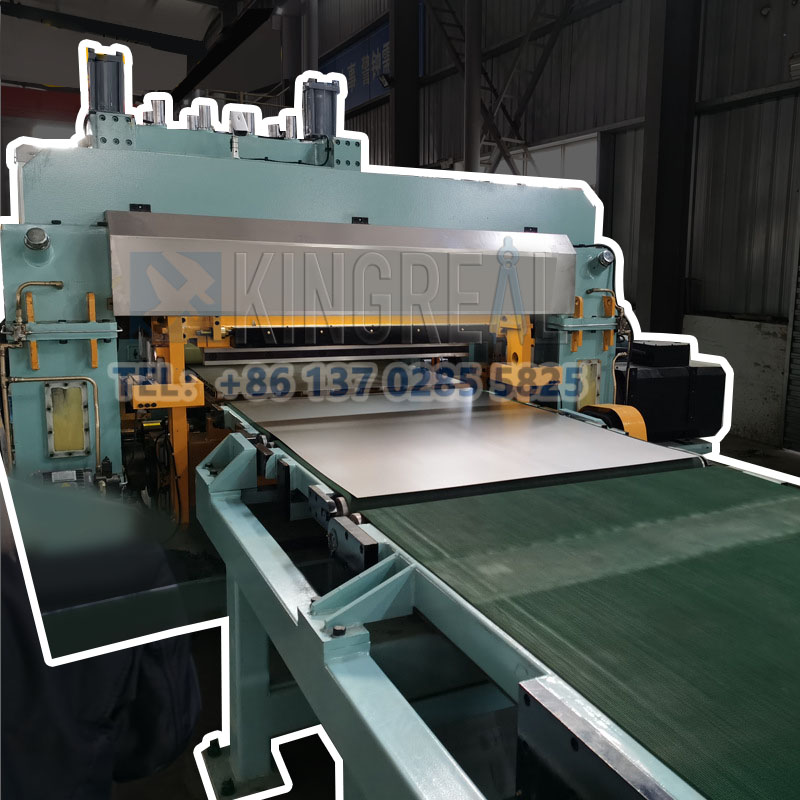

Setelah berkomunikasi dengan staf KINGREAL, pelanggan UEA dengan jelas menyatakan keinginannya untuk membelipemotongan geser terbang sesuai panjang garisPeralatan potong panjang dengan metode geser terbang KINGREAL memiliki kemampuan untuk menggunting pada kecepatan tinggi, dengan kecepatan geser hingga 80 m/menit, dan tidak perlu berhenti selama proses pengguntingan, yang mana sangat meningkatkan efisiensi produksi.

Desain garis potong geser terbang memungkinkan material logam digunting dengan lancar dan tanpa hambatan, sehingga mengurangi waktu yang terbuang karena waktu henti. Pelanggan sangat puas dengan kinerja peralatan potong logam ini, karena yakin bahwa hal itu tidak hanya meningkatkan efisiensi produksi, tetapi juga mengoptimalkan proses produksi dan menghemat biaya tenaga kerja.

Kasus yang sukses ini menunjukkan keunggulan teknis dan kemampuan adaptasi pasar KINGREAL di bidang peralatan pemotongan logam sesuai panjang.

Tali Potong Panjang Sedang di Indonesia

Itugaris potong berukuran sedangdirancang oleh KINGREAL untuk pelanggan Indonesia dapat memproses material logam dengan kisaran ketebalan 0,3-6 mm. Pelanggan Indonesia menghadapi banyak masalah saat mencari peralatan potong logam yang sesuai: ia menginginkan kinerja peralatan yang stabil dan ingin mampu memotong pelat logam dengan kisaran ketebalan yang luas.

Setelah berkomunikasi secara mendalam dengan pelanggan Indonesia, teknisi KINGREAL merancang jalur potong berukuran sedang berdasarkan kebutuhan pelanggan Indonesia untuk memenuhi persyaratan kinerja pelanggan. Jalur potong baja tahan karat berjalan lancar, produk yang digunting bebas gerinda, panjangnya akurat, dan sepenuhnya memenuhi standar produksi pelanggan Indonesia.

Melalui keberhasilan implementasi proyek ini, pelanggan Indonesia tidak hanya meningkatkan efisiensi produksi, tetapi juga meningkatkan daya saing pasar dan memperluas cakupan bisnisnya. Kasus ini sepenuhnya menunjukkan kemampuan profesional KINGREAL dalam solusi peralatan pemotongan logam yang disesuaikan.

Garis Potong Sederhana Sesuai Panjangnya Di Qatar

Pelanggan di Qatar baru saja memasuki industri pemrosesan dan manufaktur logam dan dihadapkan dengan masalah skala produksi yang kecil dan area bengkel yang terbatas. Setelah memahami kebutuhan pelanggan Qatar, teknisi KINGREAL mengusulkan rencana untuk merancangperalatan potong sederhanaMeskipun merupakan peralatan potong sederhana, peralatan ini tetap memiliki karakteristik operasi yang stabil, pemotongan tanpa gerinda, dan panjang yang akurat.

Desain peralatan potong sederhana ini memungkinkan pelanggan untuk segera mulai berproduksi guna memenuhi permintaan pasar. Berkat pengoperasian peralatan yang sederhana, pekerja pelanggan dapat segera memulai dan memastikan efisiensi dan keamanan produksi.

Melalui kasus yang sukses ini, pelanggan Qatar tidak hanya menyelesaikan konstruksi awal tata letak produksi, tetapi juga membangun fondasi produksi yang baik, yang menjadi landasan yang kokoh untuk ekspansi bisnis di masa mendatang. Kinerja KINGREAL dalam proyek ini semakin mengukuhkan reputasinya di hati para pelanggan.

Layanan Pengepakan & Pengiriman