Mesin Pembuat Baki Kabel

Mesin pembuat baki kabel KINGREAL digunakan untuk memproduksi baki kabel berbagai jenis dan ukuran, dan dapat menyediakan sistem baki kabel lengkap kepada pelanggan.

- KINGREAL

- Cina

- informasi

- Download

Video Tentang Mesin Pembuat Baki Kabel

Mesin Pembuat Baki Kabel KINGREAL

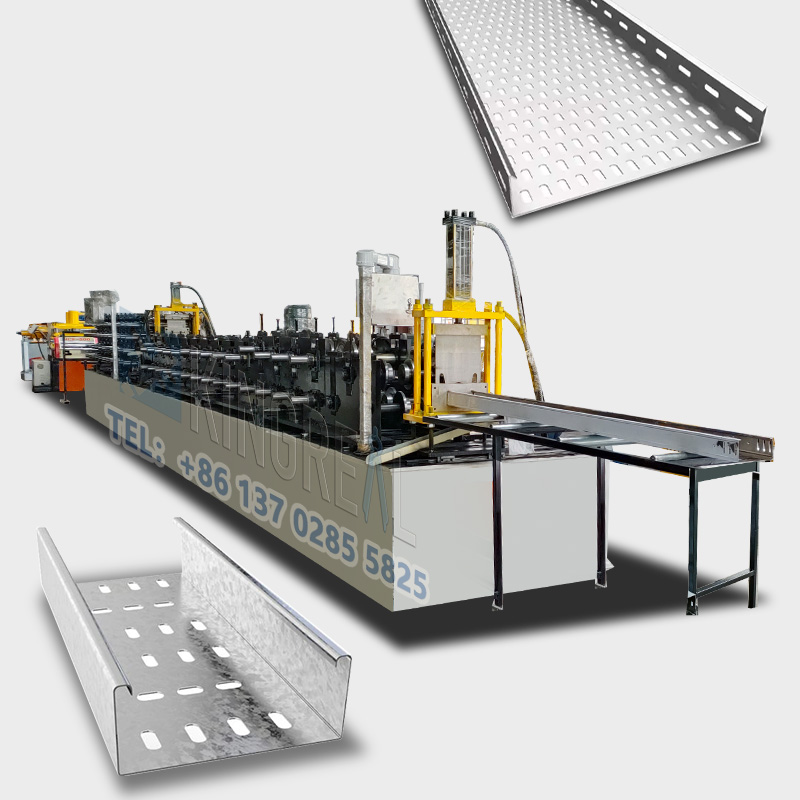

Mesin Pembuat Baki Kabel KINGREAL digunakan untuk memproduksi baki kabel. Sistem ini dapat mengangkut kabel dengan aman untuk mencegah benturan, panas berlebih, dan kebakaran. KINGREAL dapat menyediakan berbagai jenis solusi manufaktur mesin baki kabel kepada pelanggan, termasuk: Mesin Saluran Rel DIN, Mesin Pembentuk Baki Kabel Dasar Padat, Mesin Baki Kabel Berlubang, Mesin Baki Kabel Palung. Dan berdasarkan berbagai kebutuhan produksi pelanggan, seperti lebar, ketebalan, tinggi gulungan logam, komponen parameter mesin baki kabel akan disesuaikan untuk melengkapi desain akhir mesin pembuat baki kabel. |  |

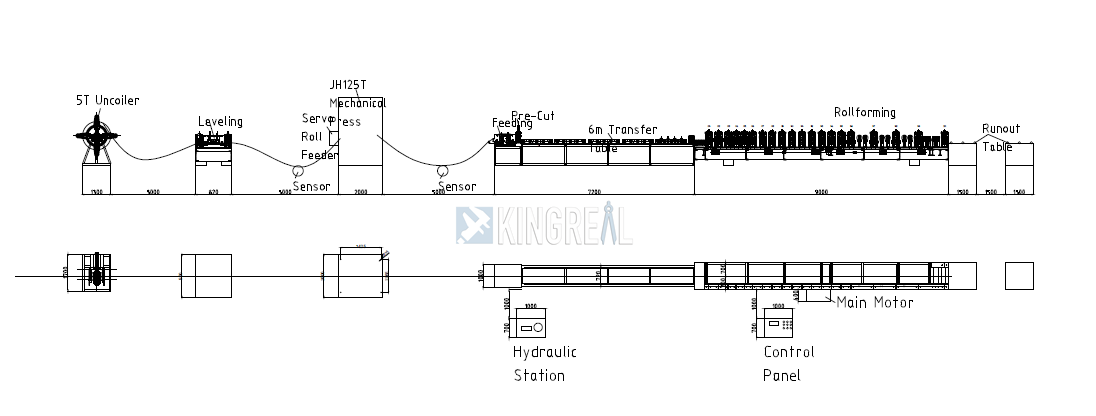

Proses Kerja Mesin Baki Kabel

Decoiler - Mesin Leveling - Punch Hidrolik - Mesin Pemotong - Mesin Roll Forming - Meja Runout

Parameter Mesin Pembuat Baki Kabel

| Mesin Pembuat Baki Kabel | |

| Barang | Spesifikasi |

| Kekuatan | – Transmisi: 22kw – Motor – Pompa: 22kw |

| Berat mesin | 14 – 26 ton |

| Dimensi | P=14m; L=2,2m; T=1,8m |

| Kecepatan Pembentukan | 16m/menit |

| Stasiun rol | 22 – 26 |

| Sistem transmisi | Motor listrik dan Gearbox |

| Sistem Pemotongan dan Pelubangan | Silinder hidrolik |

| Sistem kontrol | PLC, HMI otomatis dapat diprogram |

| Mengubah ukuran | Dengan sekrup |

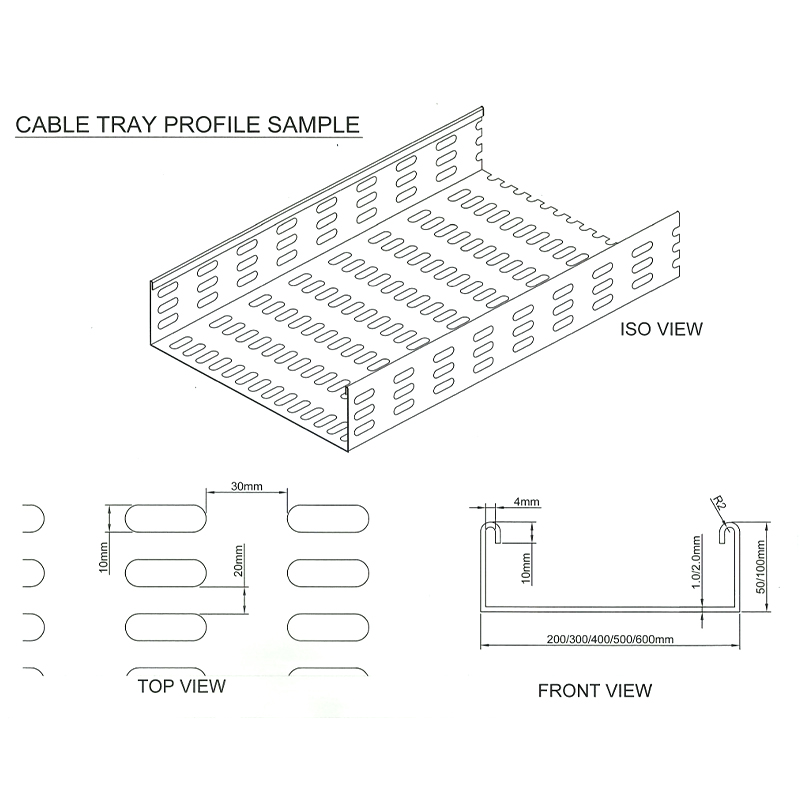

| Ketebalan material | 1 – 2 mm |

| Lebar material maks | 830 mm |

| Kekuatan Luluh Material | G450 – G550 MPa |

Komponen Utama Mesin Baki Kabel

– Unit Pengumpanan Tekan Baki Kabel untuk Mesin Baki Kabel Sistem pengumpanan mesin pembuat baki kabel KINGREAL mencakup decoiler, pelurus, dan pengumpan, serta mengadopsi kontrol servo untuk memastikan pengumpanan yang akurat. Decoiler berfungsi untuk mengurai gulungan bahan baku, sementara pelurus memastikan material tetap lurus sebelum memasuki proses pembentukan, sehingga menghilangkan bentuk gelombang yang disebabkan oleh gulungan. Penerapan sistem kontrol servo memungkinkan kontrol kecepatan dan posisi pengumpanan yang presisi, sehingga meningkatkan efisiensi produksi secara signifikan dan mengurangi pemborosan material. Melalui sistem ini, mesin pembuat baki kabel dapat beroperasi secara terus-menerus dan stabil, memastikan setiap baki kabel memenuhi standar kualitas yang tinggi. |  |

– Unit Pelubang Baki Kabel untuk Mesin Pembuat Baki Kabel KINGREAL akan memproduksi cetakan pelubang sesuai dengan gambar pelanggan dan merekomendasikan mesin pelubang yang paling sesuai kepada pelanggan, memastikan bahwa pelanggan bisa mendapatkan efek pelubangan baki kabel yang sempurna melalui mesin baki kabel KINGREAL. Desain unit pelubang memungkinkan pelubangan berkualitas tinggi dan presisi tinggi pada baki kabel dengan berbagai ketebalan dan material untuk memenuhi berbagai kebutuhan baki kabel. Dengan mengoptimalkan desain cetakan, kecepatan dan akurasi pelubangan telah ditingkatkan secara signifikan, yang secara signifikan meningkatkan efisiensi produksi. |  |

– Unit Pembentuk Gulungan Baki Kabel untuk Mesin Baki Kabel Mesin pembuat baki kabel KINGREAL dapat secara otomatis menyesuaikan lebar dan tinggi untuk menghasilkan baki kabel dengan berbagai ukuran. KINGREAL akan memproduksi mesin pembuat baki kabel dengan jumlah stasiun dan diameter poros yang berbeda-beda sesuai dengan gambar pelanggan. Fleksibilitas ini memungkinkan mesin baki kabel beradaptasi dengan berbagai kebutuhan produk, sehingga secara efektif meningkatkan daya saing pasar. |  |

– Unit Pemotong Baki Kabel untuk Mesin Pembuat Baki Kabel Sistem pemotongan mesin baki kabel KINGREAL mengadopsi pemotongan hidrolik, dan cetakan pemotongnya terbuat dari baja SKD11, diproduksi dengan mesin CNC, dan dipanaskan hingga 55-60HRC. Pemilihan material dan proses manufaktur ini memastikan daya tahan dan stabilitas alat geser, yang dapat tetap tajam selama produksi jangka panjang dan mengurangi biaya perawatan. Efisiensi tinggi sistem pemotongan hidraulik memungkinkan mesin pembuat baki kabel memotong dengan cepat, memastikan akurasi panjang dan kualitas pemotongan baki kabel, serta menghindari pemborosan material akibat pemotongan yang tidak tepat. Dengan mengoptimalkan proses pemotongan, efisiensi mesin baki kabel telah meningkat secara signifikan. |  |

1. Mesin pembuat baki kabel mengadopsi pemotongan hidrolik untuk memotong secara akurat sesuai panjang yang telah ditentukan pelanggan.

2. Panel kontrol cerdas memudahkan pekerja untuk mengoperasikan, memantau, dan menyesuaikan parameter mesin baki kabel.

3. Mesin pembuat baki kabel dapat secara otomatis membuat lubang dengan akurasi lubang yang tinggi dan konsistensi yang kuat.

4. Mesin baki kabel mengadopsi komponen berkekuatan tinggi dan tahan lama untuk memastikan stabilitas produksi dan mengurangi biaya perawatan.

5. Mesin baki kabel dapat menghasilkan baki kabel dengan berbagai ukuran dengan menyesuaikan kelompok rol.

6. Mesin baki kabel mengadopsi teknologi pembentukan gulungan canggih untuk menghasilkan baki kabel yang akurat dan berkualitas tinggi.

Berbagai Jenis Mesin Pembuat Baki Kabel

Mesin Saluran Rel DIN ● Banyak digunakan untuk memasang pemutus sirkuit dan peralatan kontrol industri di rak peralatan. Fungsi utamanya adalah memberikan dukungan mekanis penting dalam instalasi industri, mencegah rel pemandu bergeser atau bergeser, dan meningkatkan stabilitas secara keseluruhan. ●Ukuran standar: 35mm x 7,5mm dan 35mm x 15mm

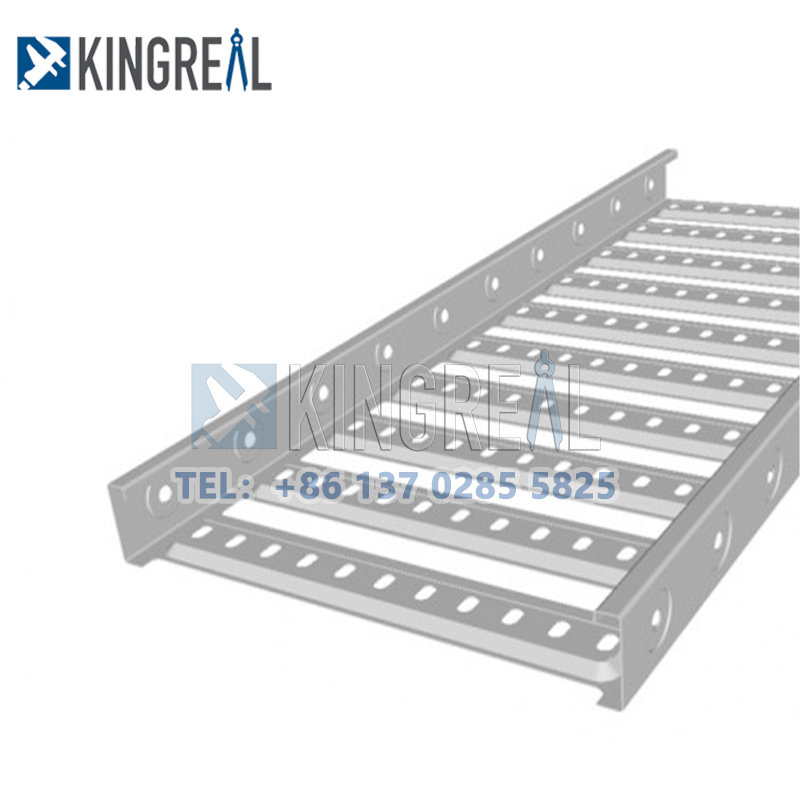

| ●Seperti tangga, dengan palang di tengah untuk penguatan, ringan, biaya rendah, sangat kuat dalam menahan beban, dan bernapas. ●Umumnya digunakan untuk memasang kabel dengan diameter lebih besar dan kabel daya tinggi dan rendah. ●Lebar standar 150, 200, 300. 450, 600, 750, 1000 mm. ●Kedalaman standar 50-150 mm. ●Panjang standar 2500 & 3000 mm.

|

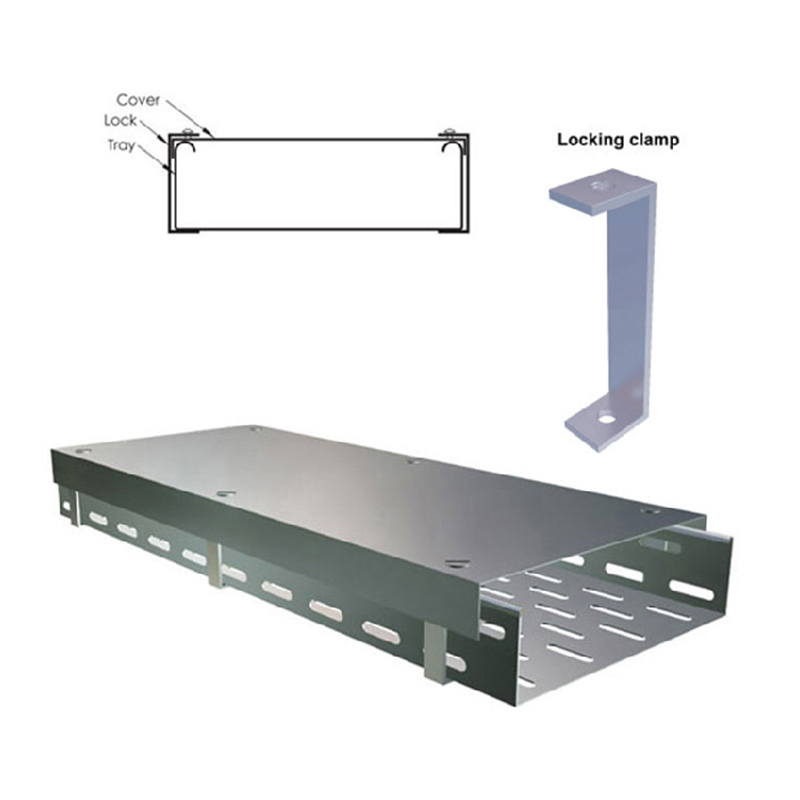

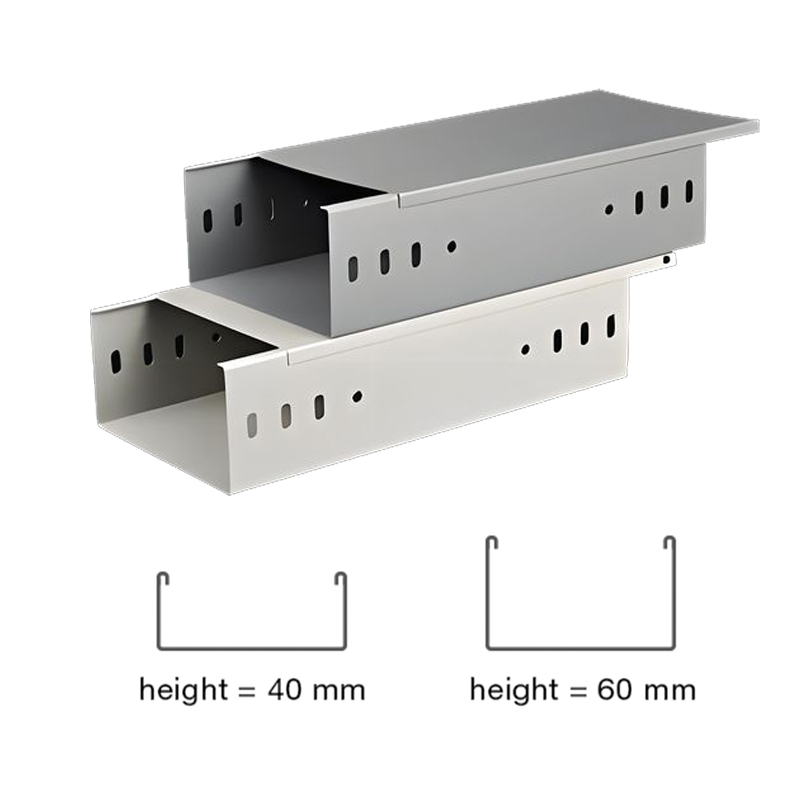

●Penutup lurus untuk baki kabel. Dengan lebar 50-300 mm, penutup ini memiliki fungsi snap-on. Penutup ini dirancang dengan snap-on cepat dan dapat dipasang dengan cepat tanpa klip penutup. ●Fungsi utamanya adalah melindungi kabel dari lingkungan luar, mencegah debu, zat korosif, dll. memasuki baki kabel, dan juga mencegah orang menyentuh kabel secara tidak sengaja.

| Mesin Baki Kabel Dasar Padat ●Ini adalah baki kabel yang tertutup sepenuhnya. Sangat cocok untuk meletakkan kabel komputer, kabel komunikasi, kabel termonuklir, dan kabel kontrol lainnya pada sistem yang sangat sensitif. Baki kabel ini dapat memberikan perlindungan dan penyembunyian di atas kepala untuk berbagai instalasi kabel. ●Diterapkan pada bentang pendek hingga menengah 1500 mm hingga 3500 mm.

|

Mesin Baki Kabel Berlubang ●Kinerja pembuangan panas yang baik. ●Lebar standar 150, 250, 300, 450, 600, 750, 1000 mm. ●Kedalaman standar 50-150 mm. ●Panjang standar 2500 mm & 3000 mm.

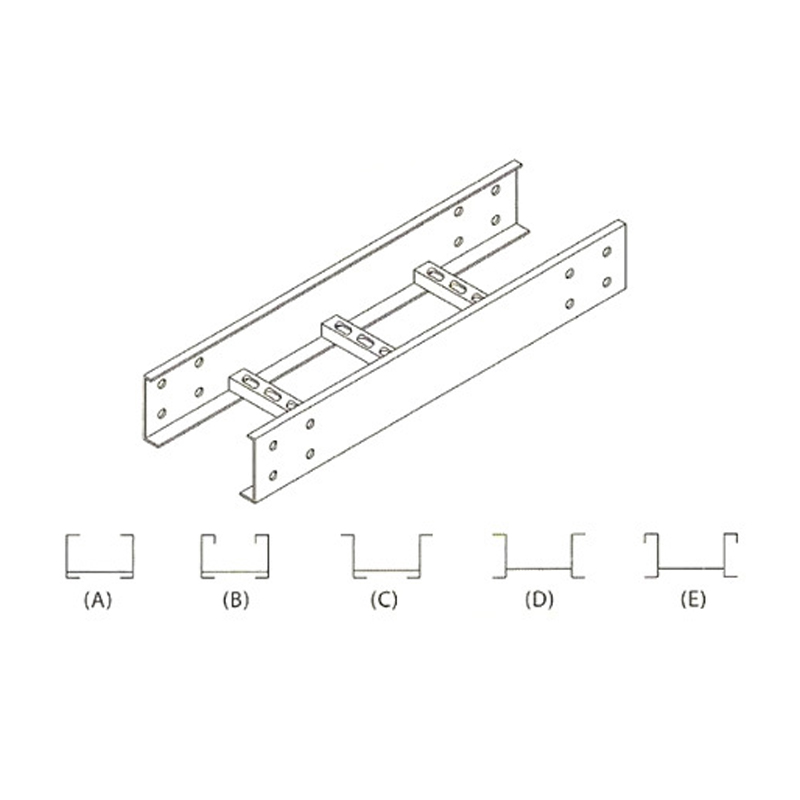

| Mesin Baki Kabel Palung ●Memberikan ventilasi sedang dan meningkatkan frekuensi dukungan kabel. ●Lebar standar 6, 12, 18, 24, 30, 36 inci. ●Kedalaman standar 3, 4, 5, dan 6 inci. ●Panjang standar 10, 12, 20 dan 24 kaki.

|

Menggambar Tentang Sistem Baki Kabel

Aplikasi Mesin Baki Kabel

Produk jadi yang dihasilkan oleh mesin baki kabel mempunyai karakteristik kinerja penopang yang kuat, kinerja pembuangan panas yang baik, pemasangan yang mudah, dan jangkauan aplikasi yang luas. Baki kabel dengan berbagai jenis dan ukuran yang diproduksi oleh mesin baki kabel terutama digunakan untuk menopang dan melindungi kabel, serta banyak digunakan di berbagai bidang seperti gedung, pabrik, dan fasilitas umum. Contoh spesifiknya antara lain pipa kabel bawah tanah di bengkel lokomotif, sistem pengkabelan di ruang komputer pusat informasi transportasi kereta api, dll. |  |